How are wine corks made? It’s a much longer process than you might imagine – it can take up to half a century to get your first quality wine cork from a tree. Following my visit to the cork harvest in Portugal, I put together a visual guide with videos, photos and explanations of how cork is made. Here’s a quick guide on video, followed by a detailed guide to the production of wine corks:

How are wine corks made? Following a cork harvest

Whether they offer an effortless whisper on release or explode with an almighty pop, pulling a cork on a bottle of wine has been an essential, and oft highly revered, part of the ceremony of wine drinking for over three centuries. But have you ever wondered how wine corks are made? I went deep into the forests of Portugal to see cork being harvested and to learn more about the life cycle of a humble cork and how it makes its way from the sandy soils of Portugal to the neck of your wine bottle.

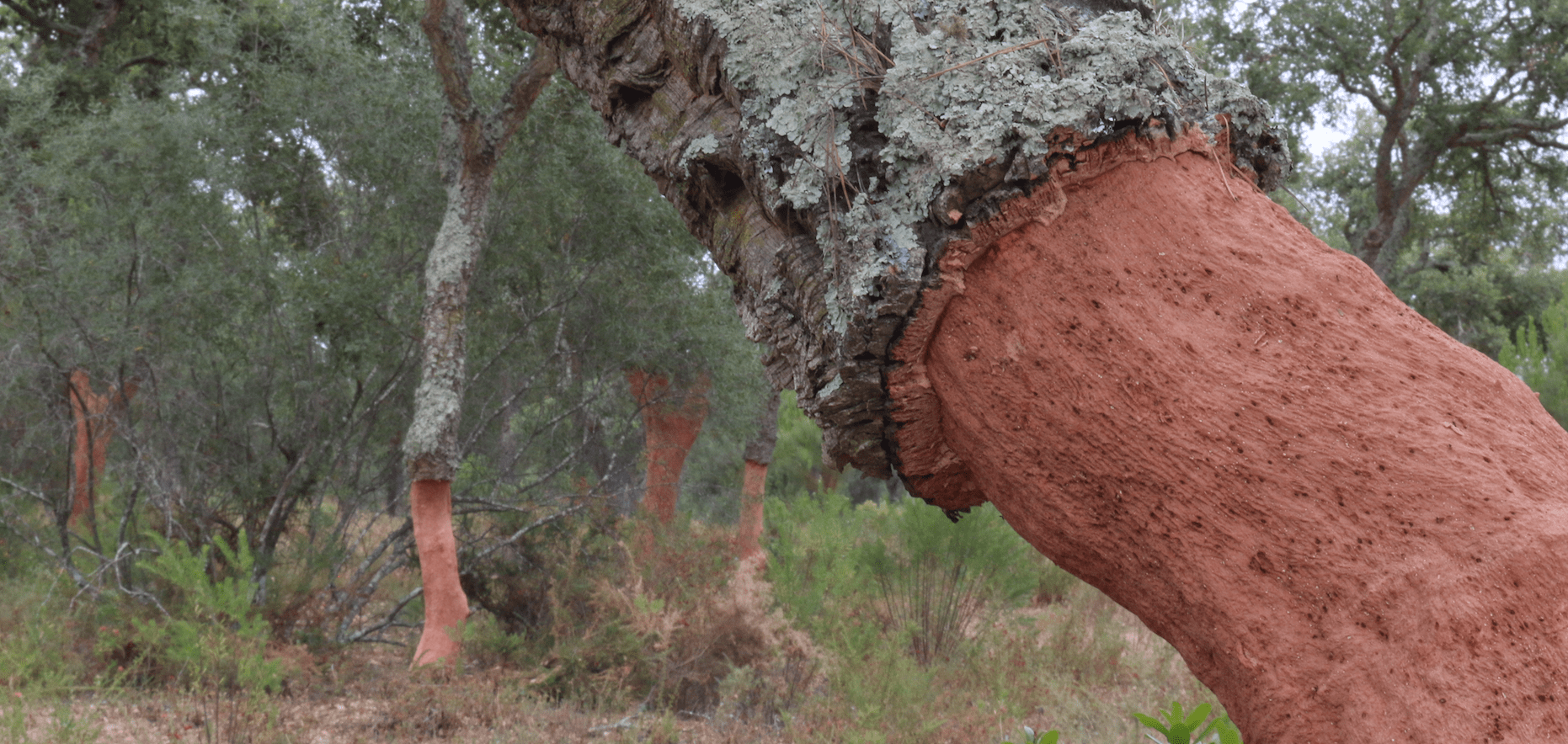

Cork forests and cork terroir

Corks are made from the bark of cork trees, from Quercus suber trees, to be precise. It sounds simple enough, but the life cycle of a cork tree is actually very complex and you usually can’t make a decent wine cork from a tree until it is almost 50 years old. Before getting into the harvest, there are several factors that are important to the ‘terroir’ of a wine cork.

Cork terroir tip 1: The climate

Cork trees are best grown in Mediterranean climates – with warm and dry summers and mild, wet winters. This is why most wine corks are produced in the Mediterranean basin: Portugal, Spain, France and on the other side of the Mediterranean Sea in Tunisia, Algeria and Morocco.

Why does cork best suit the Mediterranean climate? Portugal and the Mediterranean is the origin of the tree and the species needs warmth, sunshine and dry weather – especially in the harvest season (summer). Cork trees don’t like too much water on their roots, which brings us to…

Cork terroir tip 2: The soil

Most of the cork forests in Portugal grow in sandy soils. Sand is a very poor soil with great drainage, which means that when it does rain, the water doesn’t stick around for long.

Cork terroir tip 3: Forest density

Cork trees need a low planting density with a maximum of 60 to 80 cork trees per hectare to achieve optimum quality. If you plant too densely, the forest becomes more humid and shaded. This results in cork of lower quality, which is more likely to be affected by volatile compounds like TCA. Cork trees like sunshine, air and dry conditions.

Low-density planting and biodiversity are also important to reduce the risk of forest fires, as dense monoculture often leads to devastating fires that can rip through forests in minutes. Cork actually has a relatively low level of flammability and can resist high temperatures, which is why it is the material of choice on space shuttles, but it is always better to be safe than sorry. Another benefit of biodiversity and farming a range of agricultural products is the financial sustainability it can offer, especially with such a long-term investment as wine cork production.

How are wine corks made? The cork harvest

When you have found your spot and planted your cork trees, you need to patiently wait approximately 25 years in order to get your first wine cork harvest. This is the time that it takes for the bark of a cork tree to grow thick enough to be easily separated from the trunk and provide quality cork. This first harvest, the virgin harvest, or desbóia as they say in Portugal, still isn’t good enough quality to provide a single-piece wine cork, however. In its youth, the cork bark is irregular in shape and texture and is used for other purposes (like insulation and flooring). You need to wait for another two harvests – the third harvest of a new tree – to achieve bark that provides the thickness and quality needed for a prime, single-piece wine cork.

Although the cork tree starts to reproduce a corky layer just 30 days after harvest, it takes nine years before you can harvest your next bark. So if you are planning to get into the wine cork business, be prepared to wait at least 43 years to get your first decent wine cork. This is not the right business for anyone who is impatient!

The cork harvest is also very labour intensive. So far few ways of mechanising the process have been developed, so the harvest has to be done by hand, with a strong crew (usually men), wielding axes.

Damage from a previous harvest

The crew have to know how to handle the cork. They must angle their axe in a certain way and know to which depth they can chop, as any damage to the tree trunk can cause regrowth complications for the tree.

The matter is complicated further in that the harvest can only take place between May and August when the months – and days – are dry enough for the layer of cork to easily separate. If your harvest is interrupted by unexpected rain, you just have to wait for the weather to dry the trees out again – which may well set you back another year. In the lead-up to the harvest, the grower takes small samples at different points around the forest to see whether the trees are ready to be harvested.

How much cork does a tree produce?

On average each cork tree will produce around 1.5-2 arrobas of cork each harvest. An arroba is a special measurement unit which equates to 15 kilograms (so 23 – 30 kilograms per tree). Of that, only 5-10% will be suitable for the very top quality wine corks; the rest will be used for cheaper cork closures (or sometimes conglomerate wine corks) and other cork uses like badminton shuttlecocks, shoes and tarmac. The crème de la crème of the cork bark is always reserved for wine closures.

What’s the lifespan of a cork tree?

Cork trees can live a couple centuries. However, the average lifespan for quality cork production is between 10 and 15 harvests (depending on the individual tree), after which the cork tree can become a lot less productive. Cork trees are strictly protected, however, and so you can’t simply pull it out, unless it has a serious virus or disease. Otherwise, it has to be left until it dies of natural causes. The cork trees are protected because they create a habitat that is home to many endangered animal species, including the Iberian lynx and imperial eagle.

Who makes most of the world’s cork?

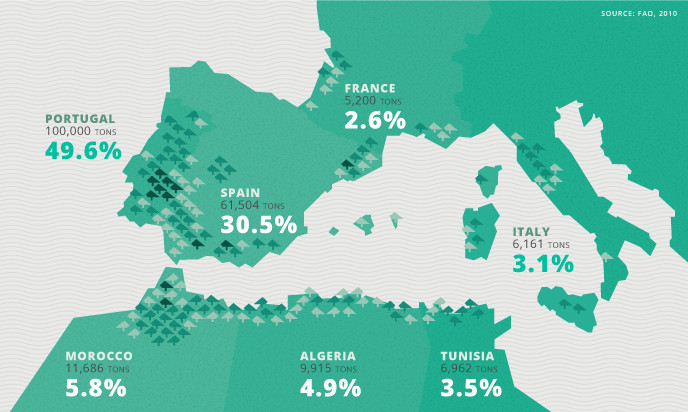

For now, it is Portugal, which produces half of the world’s cork. The company I visited in Portugal, Amorim, is the world’s largest cork producer and, like many Portuguese cork producers, they purchase the vast majority of their cork bark from small, privately-owned forests. Portugal has a third of the world’s cork forests (it purchases cork from neighbouring countries, which bolsters its production numbers) and 98% of those forests are privately owned, usually under family ownership.

Spain is hot on Portugal’s heels, producing a third of the world’s cork (although much of the cork is actually processed in Portugal) and other important Mediterranean producers include Morocco, Algeria, Tunisia, Italy and France (in descending order). Outside of the Mediterranean basin, cork is being produced in Brazil and China. However the more humid conditions aren’t considered as beneficial for quality wine cork production.

Source: Amorim

How are wine corks made? From bark to bottle

Once the sections of bark have been stripped from the cork trees, they are taken to the processing plant where they will sit (or stabilise) for a minimum of 6 months. One of the reasons cork is a remarkable material is because it is 90% air and during this stabilisation period the cork expands.

After 6 months, the cork barks are dipped into a 97°C bath of boiling water for an hour. This helps to expand the cork even more and remove any dust, other particles and volatile compounds (like TCA). The bark then releases its steam in the open air, before being sorted and categorised for its onward journey.

After 6 months, the cork barks are dipped into a 97°C bath of boiling water for an hour. This helps to expand the cork even more and remove any dust, other particles and volatile compounds (like TCA). The bark then releases its steam in the open air, before being sorted and categorised for its onward journey.

Cork barks are categorised into the different quality levels and any cork with a defect will be discarded or shredded for other uses. The lower qualities of cork might be shredded into smaller pieces which can be compressed together to make agglomerate wine corks.

Agglomerate wine corks

Higher quality cork will be cut into smaller disks, which will be used to cap the agglomerate wine corks on one or either side. These are known as technical corks, and are typically used for sparkling wine corks, for example. They have the benefit of one whole piece of cork where it counts (at the closure, where oxygen ingress is important) and the price of agglomerate cork in the middle. Single-piece wine corks (cut from just one piece of cork bark) are the highest quality, and most expensive, wine corks.

There are several stages of declassification in the cork-making process – machines and people scan the corks looking for faults, irregularities and inconsistent humidity and volume. Any piece that doesn’t fit the rigorous requirements is downgraded for a different use.

Nothing is wasted – not even cork dust

There’s no waste in cork – even the lowest quality of cork can be made into dust, which serves a purpose in other industries, such as cosmetics. This is one of the reasons why cork is considered the most sustainable and environmentally-friendly wine closure.

Wine cork quality control and the bane of TCA

TCA is a serious topic when it comes to cork. It is what almost destroyed corks reputation in the early 2000s when Australian and New Zealand winemakers practically boycotted the entire wine cork industry due to TCA faults found in their wines.

The TCA scare was enough to put several producers, and indeed a couple of countries, off cork closures. However, cork producers are much more on top of TCA these days and have reduced the cases of TCA by 95% over the last decade. This has been achieved by steaming the cork at least three times before it is used as a wine stopper. TCA is a volatile compound so it tends to evaporate at high temperatures through steam treatment. There’s also a rigorous testing process for TCA within the factory. This is done either by machines sampling the corks and testing them for TCA levels or by the rather more arduous method of sniff testing each and every cork that is shipped to a producer.

Not all corks are made equal of course, but when you do find that one perfect wine cork you can’t help but admire the patience and craftsmanship that has goes into making it. You aren’t only uncorking the history of the wine with each bottle, but also a piece of cork that was at least half a century in the making. It’s certainly changed my perspective about each bottle I pop.

- Read more on cork with our feature on the battle to conquer TCA in wine corks.

–

Cork Talk: A guide to wine cork & wine closure vocabulary

Agglomerate cork

A wine cork made by glueing together different (small) pieces of cork.

Cork taint

A broad term for undesireable smells found in a wine. This can be caused by TCA, but sometimes the cause of cork taint can also be poor storage conditions after the wine leaves the winery or using unclean barrels in the winemaking. Wine is described as ‘corked’.

Glass corks

A new wine closure made from glass (which saves you the bother of a corkscrew). Vinolok is the most popular brand.

A new wine closure made from glass (which saves you the bother of a corkscrew). Vinolok is the most popular brand.

Multipiece cork

Using several layers of natural cork to create a natural cork effect but with a slightly lower price point as a one-piece cork because it is usually taken from the offcuts of one-piece corks.

Natural cork

Refers to wine corks made from 100% cork bark.

One-piece natural cork

These are the top pop – a wine cork made from one piece of cork tree. It has succeeded in all the selection procedures and has no faults or irregularities. It is cut out (usually by a large hole punch) as one single piece, and can cost over €1 a pop.

These are the top pop – a wine cork made from one piece of cork tree. It has succeeded in all the selection procedures and has no faults or irregularities. It is cut out (usually by a large hole punch) as one single piece, and can cost over €1 a pop.

Technical cork

An agglomerate cork (made of shredded cork pieces glued together) with a solid disk of cork on either one, or both sides. It has the economical benefit of being agglomerate cork but has the quality of one-piece cork at the closures (where it matters most).

An agglomerate cork (made of shredded cork pieces glued together) with a solid disk of cork on either one, or both sides. It has the economical benefit of being agglomerate cork but has the quality of one-piece cork at the closures (where it matters most).

Technical corks are also typically used for sparkling wine, with the whole cork disk at the end that comes in contact with the wine. Agglomerate cork is better for sparkling wine bottle necks because sparkling wine corks need to be able to withstand a greater pressure without leaks or loss of pressure.

Technical corks are also typically used for sparkling wine, with the whole cork disk at the end that comes in contact with the wine. Agglomerate cork is better for sparkling wine bottle necks because sparkling wine corks need to be able to withstand a greater pressure without leaks or loss of pressure.

Screw caps

Metal caps which screw on and off of the bottle to create a watertight and (usually) airtight seal. Great for wines that you want to consume while young and retain the fruity flavours (for both red and white wines).

Synthetic wine corks

These are wine corks using other products outside of cork. They tend to have a shorter lifespan and aren’t used for ageworthy wines, but could be an economical alternative to natural cork.

TCA ( 2,4,6-trichloroanisole)

A volatile compound that can be found in cork and give an offputting or musty smell to wines (even in minute quantities). Causes cork taint.

–

Eager for more cork talk on how wine corks are made and their impact on the industry?

Subscribers have access to these detailed interviews:

Cork forestry, conservation & cork terroir

Forest engineer Conceição Santos Silva discusses forestry management in Portugal and why conservation of the cork forests is vital to the ecosystem. She describes the terroir of cork trees, their necessities and limitations, ideal conditions and the process of the cork harvest in detail. I also interview Conceição on the future of wine cork production and how forestry management will play an important role:

…

This content is exclusive for Members. Take a look at the introductory packages below to become a Member of 80 Harvests and get unrestricted access to all our content.

Thank you for supporting the journey and being part of the 80 Harvests community!

The wine cork business: Interview with Antonio Amorim

Antonio Amorim is the fourth-generation in the wine cork business and is CEO of world’s largest wine cork producer, Amorim. In this interview, he discusses the past, present and future of the business of wine corks.

Disclosure: This is not a sponsored post, however, travel expenses to Portugal’s cork forests were covered by Amorim and 80 Harvests was invited as a guest to visit the cork harvest and wine cork production plant.